Aging

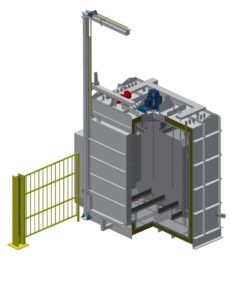

Chamber furnace with air circulation

| Oven temperature | max 350 °C |

| Batch weight | 2.000 kg |

| Batch size | 1,200 x 2,000 x 2,000 mm (L x W x H) |

| Heating | Direct electric heating |

The compact chamber furnace can be loaded by forklift as well as by movable furnace grate. The furnace door can be moved and pressed on by electric motor. The chamber furnace forms the core for the following modular expandable equipment:

Air quench / air shower

Water/polymer quenching

Charging equipment

Chamber furnace line

Chamber furnace line

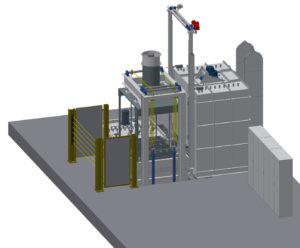

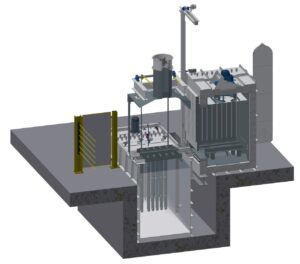

Chamber furnace with quenching bath

| Oven temperatures | max. 560 °C |

| Heating capacity | 1.200 kg/h |

| Batch weight | 1.500 kg |

| Batch size | 1,200 x 1,500 x 1,500 mm (L x W x H) |

| Heating | Direct electric heating |

The furnace system is fed via the water quench bath using a forklift truck. The water quenching bath has a hydraulic lowering platform and can be tempered between 40 and 85°C by means of electric heating and tube cooling. The batch is transported from the chamber furnace to the quenching bath by means of a push chain. The conversion time is less than 25s. The furnace system is used for solution annealing of aluminum parts.

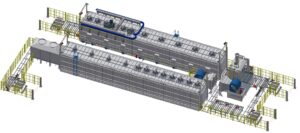

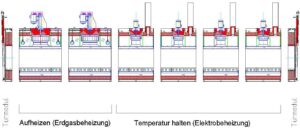

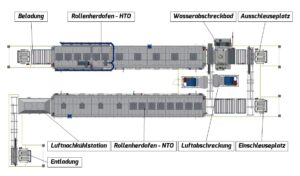

Roller hearth furnace for aluminium parts

| Oven temperatures | Solution annealing max. 560 °C |

| Heating capacity | Ageing max. 300 °C" |

| Batch weight | 6,000 kg/h |

| Batch size | max. 2,000 kg |

| Heating | 1,000 x 2,000 x 2,000 mm (L x W x H) |

The roller hearth furnaces are components of a fully automated heat treatment plant for aluminum parts. The modular roller hearth plant can be individually adapted to the required heat treatment specification. The plant can also be set up in line or in a U-shape. A subsequent extension or increase in capacity can be achieved by branching or adding modules.

Batch tracking in combination with heat treatment recipe management allows different components to be treated simultaneously in the furnace system.