Carburizing

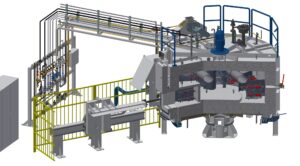

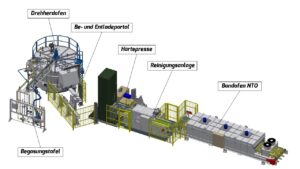

Rotary hearth furnace with hardening press

| Oven temperatures | max 950 °C |

| Heating capacity | 500 kg/h |

| Batch weight | max. 50 kg |

| Batch dimension | 500 x 500 x 150 mm (L x W x H) |

| Heating | Natural gas recuperator burner in the radiant tube |

| Furnace atmosphere | Endogas / nitrogen |

The rotary hearth is loaded or unloaded through a portal on two levels. The components are transferred to the hardening press. Directly after this, the components are linked to the washing machine and finally to the belt tempering furnace with aftercooling section.

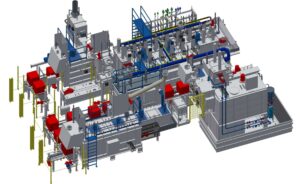

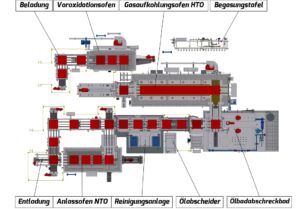

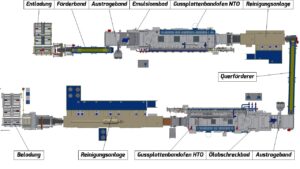

Push-through gas carburizing plant

| Oven temperatures | max 980 °C |

| Heating capacity | 1.500 kg/h |

| Batch weight | max. 380 kg |

| Batch dimension | 650 x 650 x 650 mm (L x W x H) |

| Heating | Natural gas recuperator burner in the radiant tube |

| Furnace atmosphere | Endogas / nitrogen |

| Carburizing capacity | at 0.2 mm -> 1,500 kg/h at 0.8 mm -> 700 kg/h at 1.2 mm -> 350 kg/h |

Furnace system consists of the following assemblies:

- Transport line with loading & unloading

- Pre-oxidation furnace

- Gas carburizing furnace

- Oil quenching bath

- Washing machine

- Tempering furnace

Casting plate belt furnace

| Oven temperatures | max 960 °C |

| Heating capacity | 1.100 kg/h |

| max. belt load | 152 kg/m² |

| Part weight | 2 - 2.500 g |

| Throughput width annealing furnace | 1.200 mm |

| Throughput width tempering furnace | 1.400 mm |

| Heating | Natural gas recuperative burner in the radiant tube |

| Oven atmosphere | Endogas / Nitrogen |

The cast link conveyor is overlapped and manufactured in 1.4849. The furnace is equipped with lightweight refractory brick and ceramic fiber insulation and has space for 2 atmosphere circulation units.

- N2 safety gassing

- 3 inlet photocells to control the loading height (CQI-9)

- Reversing – synchronous drive system with torque control