Annealing

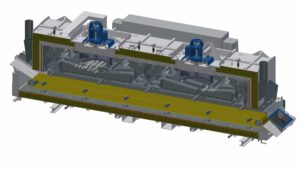

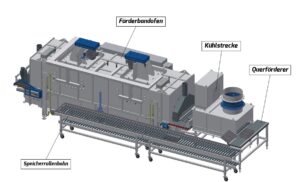

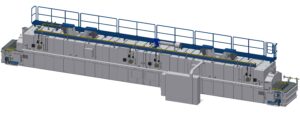

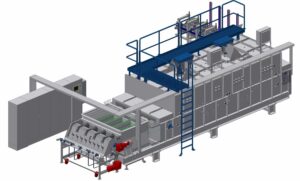

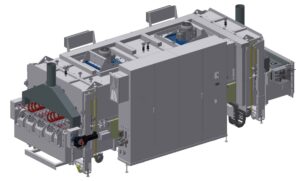

Conveyor belt furnace for hot forming

| Oven temperatures | 460 - 500 °C |

| Heating capacity | 600 kg/h |

| Part weight | 3 kg |

| Throughput dimensions (width x height) | 1.000 x 200 mm |

| Heating | Direct electric heating |

The conveyor belt furnace is loaded via the loading device. The conveyor belt is divided into three adjustable zones by means of suspended separators.

The furnace has 4 control zones with 2 air circulation fans and 2 air guiding devices. The heating is done by electric screw-in heating elements, which are installed and removed from the side.

The control elements measure the temperature of the air entering the batch chamber. This prevents the components from overheating.

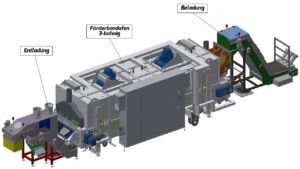

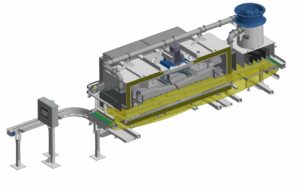

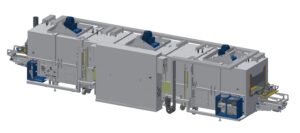

Conveyor belt furnace for tempering

| Oven temperatures | 460 - 500 °C |

| Heating capacity | 400 - 600 kg/h |

| Part weight | 1 kg |

| Throughput dimensions (width x height) | 1.000 x 180 mm |

| Heating | Direct electric heating |

The charging can be carried out in bulk in grid boxes, or via vibrating feeders or conveyor belts, and can be operated in multiple lanes.

The furnace has 4 control zones with 2 air circulating fans and 2 air guiding devices. The heating is done with electric screw-in heating elements, which are installed and removed from the side.

Directly behind the furnace is a cooling device, which provides cooling of the charge with supply and exhaust fans.

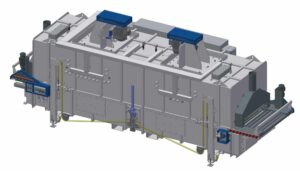

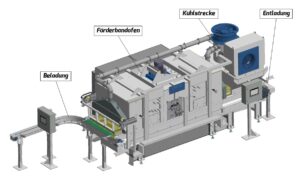

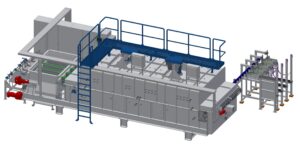

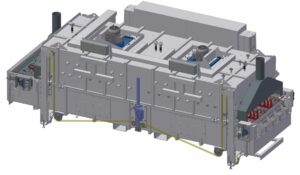

Conveyor belt furnace for tempering with cooling section

| Oven temperatures | 175 - 250 °C |

| Heating capacity | 360 kg/h |

| Part weight | 3 kg |

| Throughput dimensions (width x height) | 1.200 x 200 mm |

| Heating | Direct electric heating |

The system is fed by a pusher which pushes the material to be treated from an upstream conveyor belt onto the furnace belt. The oven belt also runs through the cooling section and transports the material to be treated to the chute, which connects to the unloading section.

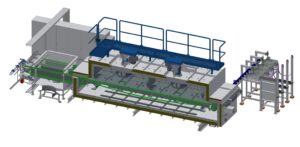

Tempering furnace for stabilizers

| Oven temperatures | 200 - 400 °C |

| Heating capacity | 1.000 kg/h |

| Part weight | 5 kg |

| Passage width | 1.700 mm |

| Heating | Direct cold air gas burner with infinitely variable output control |

The track width of the two-strand chain conveyor is variably adjustable between 450-750mm and is driven by a servo motor. Thus, different stabilizer types can be driven through the plant.

The furnace is equipped with 3 heating zones, each of which is equipped with 2 adjustable cold air gas burners and a hot gas circulator.

The cooling module can be structurally separated from the furnace or directly integrated into the furnace transport system.

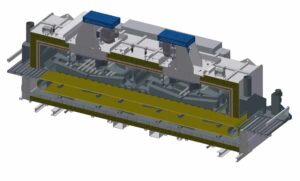

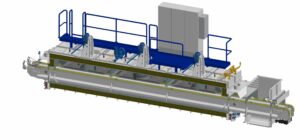

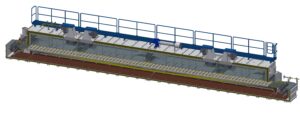

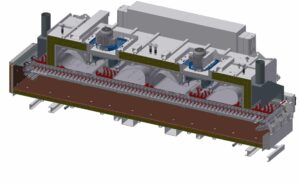

Tempering furnace for axle springs

| Oven temperatures | 350 - 450 °C |

| Heating capacity | 4.800 kg/h |

| Part weight | 5 kg |

| Passage width | 1.350 mm |

| Heating | Direct cold air gas burner with infinitely variable output control or electric heating |

The parts run through the oven in multiple strands. The drive cycles through the 4 heating zones, each of which is equipped with a hot gas circulator.

Loading & unloading can be done by robots as well as by manual loading.

Tempering furnace for profiles and pipes

| Oven temperatures | 500 °C |

| Heating capacity | 1.000 kg/h |

| Part weight | 3 kg |

| Passage width | 2.200 mm |

| Heating | Direct electric heating |

The round or profiled tubes are provided by the magazine. The tubes travel via the conveyor belt onto a roller conveyor. On their way into the furnace, the tubes are measured by a light barrier and positioned in the center of the furnace.

Controlled by a cam disk, the pipe is pushed onto the conveyor chain by a pneumatic pusher.

Complete kiln line including loading and unloading, as well as cooling station.

Chain furnace for hot forming

| Oven temperatures | 400 - 600 °C |

| Heating capacity | 600 kg/h |

| Part weight | variable |

| Passage width | 400 x 800 x 200 mm (L x W x H) |

| Heating | Direct electric heating |

Charged furnace grates or baskets are fed into or discharged from the furnace via pneumatic transfer cars. By means of corresponding loading recipes, a wide variety of batches can be parameterized for loading and unloading.

Conveyor chain furnace for warming up

| Oven temperatures | 280 °C |

| Heating capacity | 600 kg/h |

| Batch weight | variable |

| Throughput dimensions (width x height) | 1.300 x 160 mm |

| Heating | Direct electric heating |

The carriages are transported through the oven via two steel conveyor chains. Incremental encoders at the chain deflections allow the transfer positions of the carriages to be transferred to robots or gantry grippers with millimeter accuracy, irrespective of temperature and aging-related chain elongation.

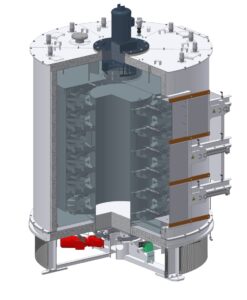

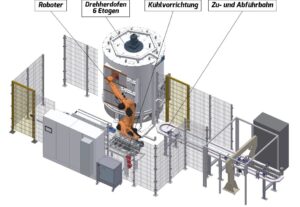

Rotary hearth furnace for transmission shafts

| Oven temperatures | 300 °C |

| Heating capacity | 500 kg/h |

| Batch weight | 2 - 5 kg |

| Batch size (length x diameter) | 400 x 150 mm |

| Heating | Direct electric heating |

The workpieces are placed by robot through the door onto the support, which is connected to the slewing ring. The six-tier turntable is driven by a geared motor and rotated further by a certain angle of rotation so that an already heated workpiece can be removed.

To prevent excessive heat loss during loading and unloading of the tempering furnace, there are 3 furnace doors.

In the cooling section, the workpieces are cooled down and then placed on the discharge conveyor by means of robots.

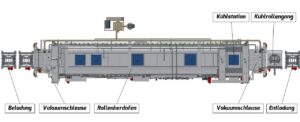

Roller hearth furnace with vacuum lock

| Oven temperatures | max. 550 °C |

| Heating capacity | 1.200 kg/h |

| Batch weight | max. 650 kg |

| Batch dimension | 930 x 850 x 850 mm (L x W x H) |

| Heating | Indirect electric heating |

| Furnace atmosphere | Nitrogen |

The gas-tight roller hearth furnace is used for heat treatment in a protective gas atmosphere (nitrogen) up to a temperature of 550°C.

The vacuum locks are pumped out to 0.1 mbar via a central vacuum pumping station and then flooded with nitrogen.

The roller hearth furnace is electrically heated and divided into 3 heating zones.

In the cooling station, the annealing material is cooled under inert gas to prevent oxidation.