Cleaning systems

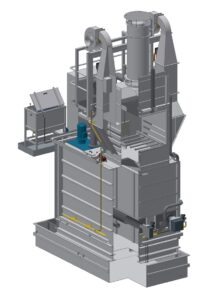

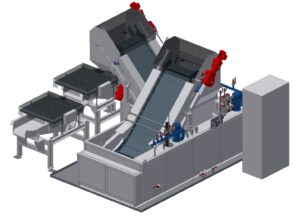

Surge cleaning system

| Batch size | 1.200 x 850 x 950 mm (L x W x H) |

| Bath volume | 15.000 l |

| Bath temperature | 60 °C |

| Heating water | Natural gas burner |

| Drying temperature | 120 °C |

After the batch has entered the cleaning system, the doors close and the cleaning process begins. Pumps convey the water into flood boxes which “rain” the water evenly onto the batch.

After cleaning, dripping takes place. In addition, the batch is dried by air flow through radial fans. Optionally, the air can be heated electrically by screw-in heating elements.

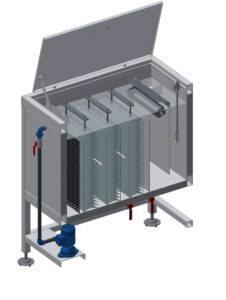

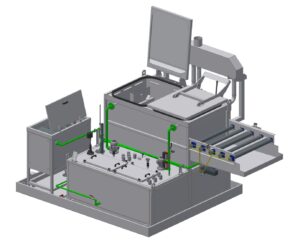

Oil separator with oil skimmer

| Bath dimensions | 1.450 x 1.500 x 900 mm |

| Bath volume | 350 l |

| Bath ingredients | Detergents, floating oils, etc. |

The oil separator can achieve a separation rate of over 90% depending on the surfactant-oil mixture and the retention time. Due to the optimized design and replaceable cassettes, maintenance and cleaning can be carried out easily and quickly.

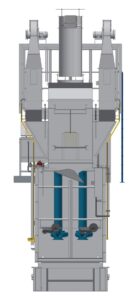

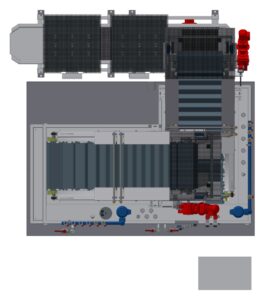

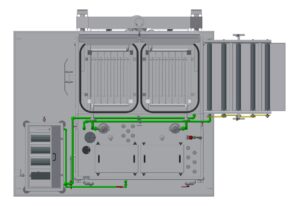

Multi-chamber cleaning system

| Batch size | 600 x 500 x 600 mm (L x W x H) |

| Bath volume | 2 x 1.700 l |

| Bath temperature | 80 °C |

| Heating | Heat exchanger |

After the batch has entered the cleaning system, the doors close and the cleaning process begins. Pumps deliver the water into flood boxes which “rain” the water evenly onto the batch.

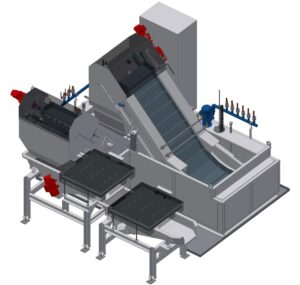

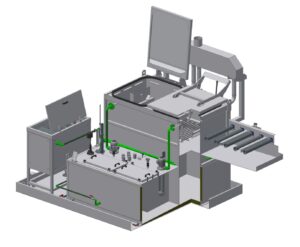

Salt purification plant

| Batch size | Small components |

| Bath volume | 2 x 2,000 liters |

| Bath temperature | 50 °C |

| Heating | electric |

Small components are conveyed to the chambers of the cleaning system via conveyor belts. Additional spray pipes clean the components on the conveyor belts. An oscillating conveyor with heating elements dries the components after the cleaning process.

Cleaning system for baskets

| Batch size | 750 x 750 x 150 mm (L x W x H) |

| Bath volume | 3 x 1,700 liters |

| Bath temperature | 70 °C |

| Heating | Heat exchanger |

The baskets to be cleaned are placed in one of the chambers of the cleaning system via a loading portal. A pump delivers water through nozzles into the chamber. Additional air nozzles ensure uniform quenching of the small components and the baskets. The baskets are transported from chamber to chamber by means of a loading portal. Rising vapors, such as salt vapors, are extracted via an evaporator to recover the quenching salt.