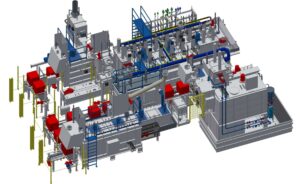

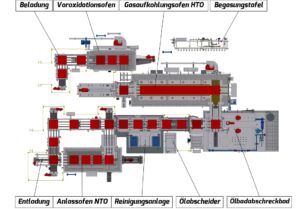

Pusher furnaces

Push-through gas carburizing system

| Oven temperatures | max 980 °C |

| Heating capacity | 1.500 kg/h |

| Batch weight | max. 380 kg |

| Batch dimension | 650 x 650 x 650 mm (L x W x H) |

| Heating | Natural gas recuperator burner in the radiant tube |

| Furnace atmosphere | Endogas / nitrogen |

| Carburizing capacity | at 0.2 mm -> 1,500 kg/h at 0.8 mm -> 700 kg/h at 1.2 mm -> 350 kg/h |

Furnace system consists of the following assemblies:

- Transport line with loading & unloading

- Pre-oxidation furnace

- Gas carburizing furnace

- Oil quenching bath

- Washing machine

- Tempering furnace

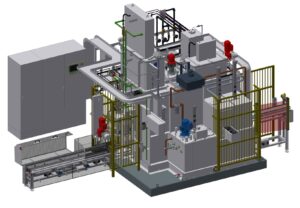

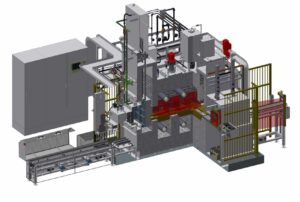

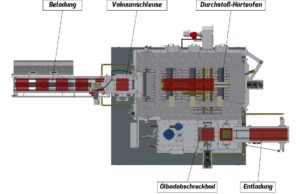

Puncture hardening system

| Oven temperatures | max 930 °C |

| Heating capacity | 100 kg/h |

| Batch weight | max. 25 kg |

| Batch dimension | 300 x 300 x 300 mm (L x W x H) |

| Heating | Indirect electric heating |

| Furnace atmosphere | Ammonia |

The furnace system consists of the following assemblies:

- Loading

- Vacuum lock

- High temperature furnace with ammonia splitter

- Oil bath

- Unloading